10 Kmolh of a Saturated Liquid Feed That is 40 Mol Be

Question

Chemical Process Calculations

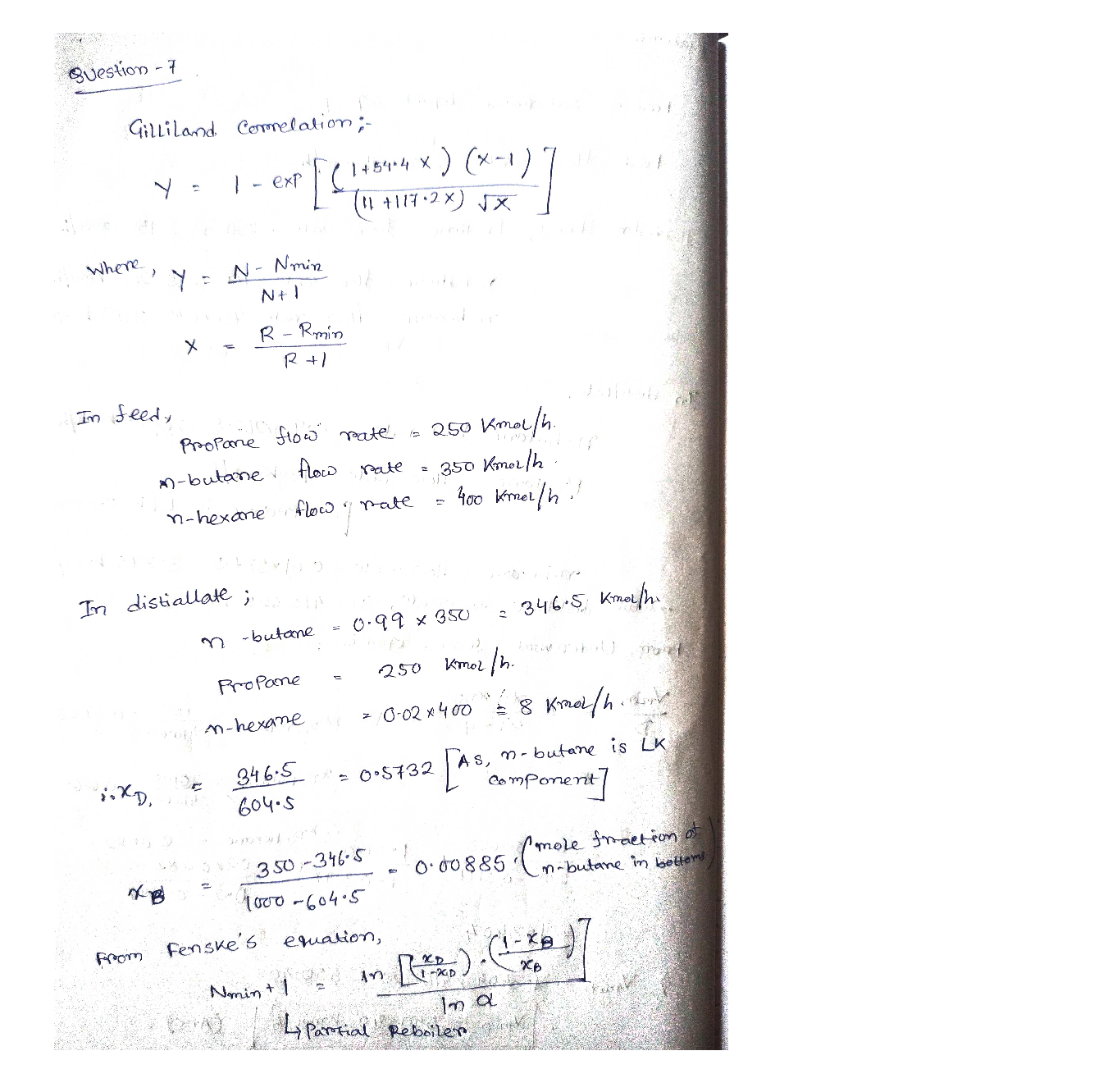

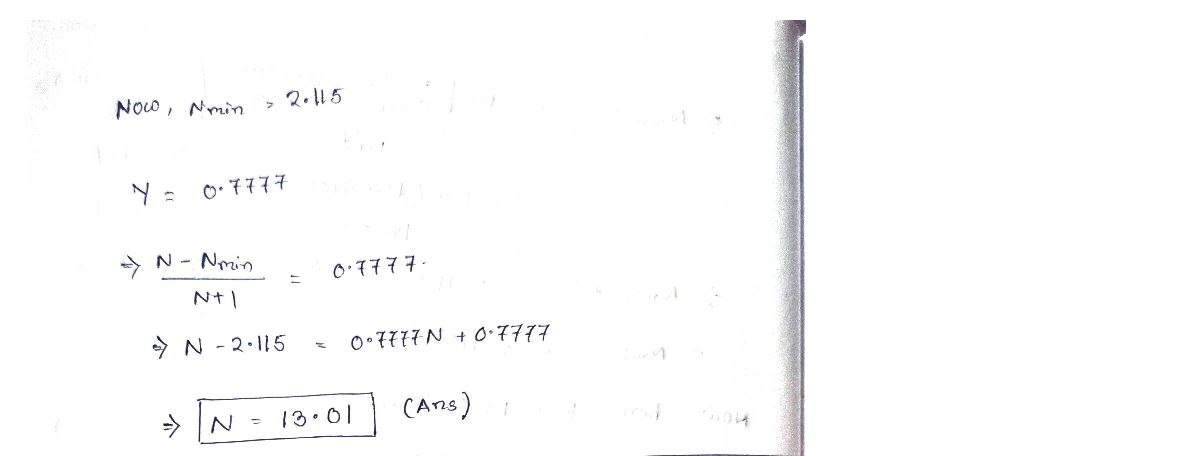

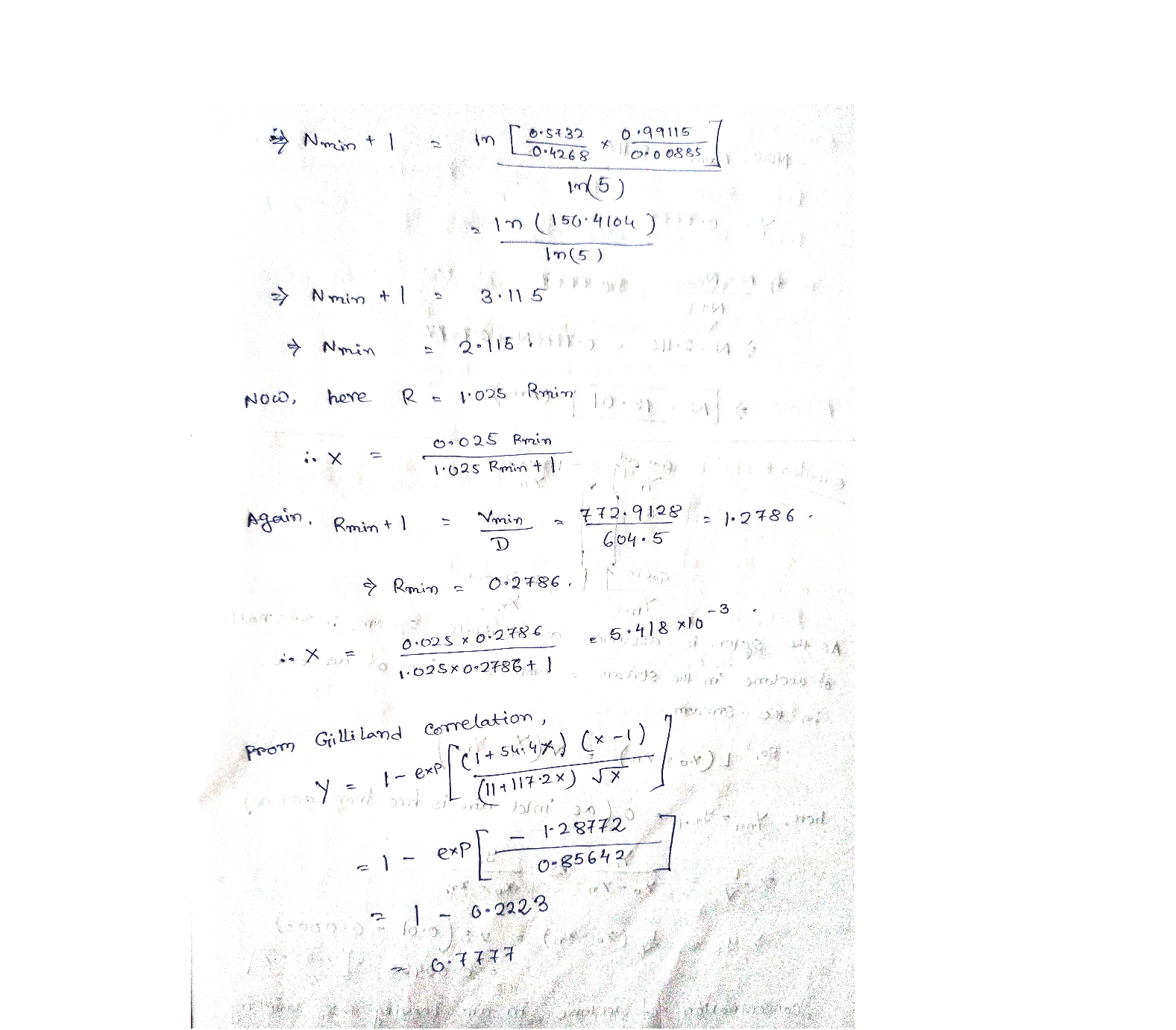

A saturated liquid feed of 1000 kmol/h consists of 25 mol% propane, 35 mol% n-butaneand 40 mol% n-hexane.

A distillate recovery of 99 mol% n-butane and bottoms recovery of 98 mol% n-hexane isdesired.

\text { The average relative volatility is } \alpha_{\text {propane }-\text { butane }}=2.04 \alpha_{\text {butane }-\text { butane }}=1.00 \mathrm{and}

\alpha_{\text {hexane-butane }}=0.2

Constant molar overflow (CMO) is valid. Reflux is returned as a saturated liquid. Thecolumn has a partial reboiler and a total condenser.

\text { Using Gilliland correlation, calculate the total number of stages if } R=1.025 \times R_{\min -}

Answer

Verified

Related Questions

Question 52874

Chemical Process Calculations

2.17.6: Two distillation columns with ethanol, butanol, and propanol.

Two distillation columns, which are overseen by engineers Gianna and Peter, separate three components. A liquid mixture enters the first column at 536 kg/s and contains 35.0 mass % ethanol (C₂H5OH), 15.0 mass % propanol (C3 H7 OH), and the balance butanol (C4 H9 OH). The bottom product stream of the first column contains 93.1 mass % B and no E, and 95.1% of the B in the feed stream is recovered in the bottom product stream. The overhead product of the first column is used as the feed stream to the second column. The overhead product from the second column contains 92.1% of the E inthe feed to this column. The composition of the overhead product stream is 91.5 mass % E and the balance P. Find the component mass flow rates (kg/s) exiting in the overhead product of the first distillation column. Stream numbering is same as PFD for question 1.

m3,p = Ex: 74.3kg/s

m3, EEx: 284 kg/s=

m3, B =Ex: 15.7kg/s

Read More

Question 52873

Chemical Process Calculations

2.17.7: Two distillation columns with three components.

A pair of distillation columns are being monitored by Beatrix and Enrico. Benzene (B), toluene (T), and xylene (X) are fed to the first distillation column. The overhead product of the first column contains only benzene and toluene. Toluene is fed to the first column at 1020 mol/hr while 74.4% of the benzene fed to the first column ends up in the overhead product. The stream exiting the bottom of the first column has a flow rate of 1590 mol/hr with 28.5 mol % benzene, 23.8 mol% toluene, and the rest xylene. The bottoms product from the first column is fed to a second distillation column. Pure xylene exits the bottom of the second column while the overhead product contains only benzene and toluene. Determine the following three unknowns.

Flow rate of xylene exiting the second column = Ex: 515 mol/hr

Mole fraction of toluene exiting the second column = Ex: 0.582

Flow rate of benzene exiting the overhead product of the first column = Ex: 1.50E mol/hr

Read More

Question 52872

Chemical Process Calculations

2.17.8: Making orange juice concentrate.

Maximus and Theodora are optimizing a steady state processing making orange juice concentrate. A stream of oranges (0) and a stream of water (W, H₂O) enter a juicing machine. The exit stream from the juicing machine contains 55.8 kg/hr orange juice (OJ, MW = 108), 21.3 kg/hr pulp solids (PS), and 43.5 kg/hr water. The exit stream from the juicing machine enters a filter. The filter removes all of the pulp solids and 20.2% of the water entering the filter as one exiting stream. The other stream exiting the filter contains water and orange juice. The water/orange juice mixture is finally sent to an evaporator to produce a concentrate stream (80.1 wt% orange juice and the balance water) and a stream of pure water. The pure water is recycled, mixed with a fresh stream of pure water, and fed into the juicing machine. Determine the following three unknowns.

Mole fraction of orange juice in the concentrate stream =Ex: 0.309

Mass flow rate of water entering the evaporator =Ex: 30.9 kg/hr

Mass flow rate of water entering the overall system =Ex: 16.8 kg/hr

Read More

Question 52871

Chemical Process Calculations

2.17.9: Preheater and distillation column.

A preheater and distillation column are maintained by engineers Marcella and Julius. A stream of pure acetone (A, C3H6O) and a stream containing acetone, ethanol (E, C2H5OH), and butanol (B, C4H, OH)entering the preheater. One stream exits the preheater containing 144 mol/min butanol, some acetone,and some ethanol; the mole fractions of butanol and ethanol are 0.209 and 0.412, respectively. The stream of pure acetone entering the preheater is 2.42 times larger than the component flow rate of acetone in the other stream entering the preheater. The stream exiting the preheater enters a distillation column, and all of the entering butanol exits in the bottom product stream. The recoveries in the overhead product, which is defined and the ratio of component flow rate exiting to component flow rate entering the distillation column, of acetone and ethanol are 83.1% and 59.2%, respectively. Determine the following three unknowns.

Mass fraction of apple in the solid waste =Ex: 0.632

Total flow rate of the concentrate =Ex: 8.82kg/min

Flow rate of pure water entering the overall system =Ex: 8.95kg/min

Read More

Question 52870

Chemical Process Calculations

Engineers Sophia and Giles are modifying a process to make concentrated apple cider starting from a slurry - a slurry is a mixture of solids in a liquid that can normally be pumped. A slurry made with apple shaving a mass fraction of 0.422 and the balance water is fed to a juicer at a rate of 26.2 kg/min. Seventy percent of the apples entering the juicer leave as part of the solid waste stream (containing apples and water). The primary product from the juicer is cider (35.3 wt% apples and 64.7 wt% water). The cider is sent to an evaporator where concentrate - apple concentration increases to 51.5 wt% - is produced along with a stream of pure water that is recycled. The pure water stream leaving the evaporator is mixed with fresh water entering the process. The combined water stream mixes with pristine apples entering the process to create the slurry. Determine the following three unknowns.

Mass fraction of apple in the solid waste = Ex: 0.632

Total flow rate of the concentrate = Ex: 8.82 kg/min

Flow rate of pure water entering the overall system = Ex: 8.95kg/min

Read More

Question 40615

Chemical Process Calculations

Answer the following question, using the equilibrium diagram of water-ethylene glycol-furfural system given in following link

Determine the percentage of water when furfural composition is 60 wt.%.

Read More

Question 40614

Chemical Process Calculations

It is desired to separate methanol (CH3OH) from methanol-water mixture in a sieve plate column operating at 2 atm, 83.2 °C (methanol boiling point at 2 atm), and 80% of the flooding velocity.

The spacing of the trays is 600 mm and the vapour and liquid flow rates are 650 kmol/hrand 2750 kmol/hr, respectively.

Assume ideal gas law, the density of water as 1000 kg/m and that the vapour is entirely methanol and liquid is entirely water.

Calculate the liquid-vapour flow factor

Read More

Question 40613

Chemical Process Calculations

It is desired to strip acetone from an acetone-water mixture into an air stream

The system operates isothermally at 20 °C and a total pressure of 300 mm Hg.

The inlet air is pure.

The column operates at L/V = 2.5

The entering liquid concentration is 1 mol% acetone and the measured outlet liquid concentration is 0.03 mol% acetone.

Assume that equilibrium is of the form y = mx

Assume dilute system.

Determine the concentration of acetone in air (in mol%) leaving the stripping column.

Read More

Question 40612

Chemical Process Calculations

A saturated liquid feed of 1000 kmol/h consists of 25 mol% propane, 35 mol% n-butaneand 40 mol% n-hexane.

A distillate recovery of 99 mol% n-butane and bottoms recovery of 98 mol% n-hexane isdesired.

\text { The average relative volatility is } \alpha_{\text {propane }-\text { butane }}=2.04 \alpha_{\text {butane }-\text { butane }}=1.00 \mathrm{and}

\alpha_{\text {hexane-butane }}=0.2

Constant molar overflow (CMO) is valid. Reflux is returned as a saturated liquid. Thecolumn has a partial reboiler and a total condenser.

\text { Using Gilliland correlation, calculate the total number of stages if } R=1.025 \times R_{\min -}

Read More

Question 40611

Chemical Process Calculations

A saturated liquid feed of 750 kmol/h consists of 20 mol% propane, 35 mol% n-butane and 45 mol% n-hexane.

A distillate recovery of 98 mol% n-butane and bottoms recovery of 99 mol% n-hexane is desired.

\text { The average relative volatility is } \alpha_{\text {propane-butane }}=2.04 \alpha_{\text {butane-butane }}=1.00 \mathrm{and}

\alpha_{\text {hexane-butane }}=0.2

Constant molar overflow (CMO) is valid. Reflux is returned as a saturated liquid. The column has a partial reboiler and a total condenser.

Calculate the total vapour flow rate in the enriching section at minimum reflux (Vmin) in kmol/h

D = 410.625 kmol/h

\phi=0.3197 \text { [Trial and Error] }

Read More

Submit query

Getting answers to your urgent problems is simple. Submit your query in the given box and get answers Instantly.

Success

Assignment is successfully created

Source: https://tutorbin.com/questions-and-answers/a-saturated-liquid-feed-of-1000-kmolh-consists-of-25-mol-propane-35-mo

0 Response to "10 Kmolh of a Saturated Liquid Feed That is 40 Mol Be"

ارسال یک نظر